LONG TERM PROCESS CONTROL FOR BIOGAS PLANTS – THE IMPORTANCE OF BICARBONATE PARAMETER

For efficient biogas production, sludge bacteria require a pH in the range of about 6.5 to 8. A stabilization of the pH in this area is mainly achieved ( 85) by the bicarbonate (= buffer substance) released in large quantities during anaerobic degradation.>

Process disturbances regularly lead to increased levels of free fatty acids (FFA) or decreasing bicarbonate levels, as the acids consume bicarbonate. However, the buffering effect of the bicarbonate hardly reduces the pH at first.

Only when the disturbance lasts for a long time and the stock of bicarbonate is largely exhausted, it comes to a rapid drop in pH and subsequently to a reduction or in extreme cases to a failure of biogas production.

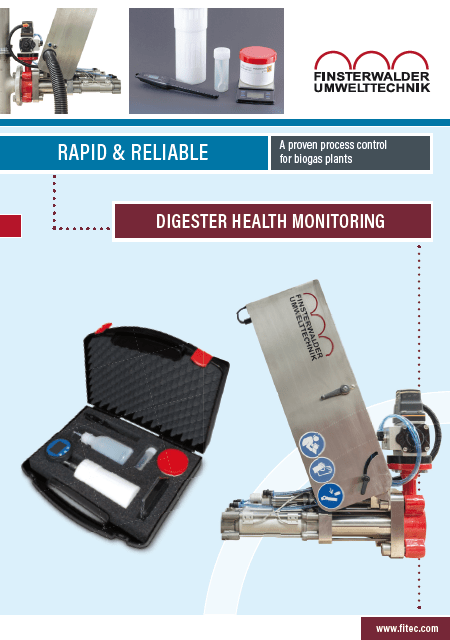

ADVANTAGES OF A PROCESS CONTROL WITH THE BICARBONATE TESTER

- In contrast to an exclusive pH value check, process faults are detected much earlier – leaving more time to avoid economic losses

- Very simple operation

- Results after 5 minutes!

- Data is easy to interpret

- Measuring technology does not require calibration

- Very low consumption costs

- Robust, long term proven measurement technology