Short Project Description

The plant AD Garmisch treats source separate collected organic waste mainly from private households. The plant is designed for a throughput of 10.000t/y. The waste is delivered into the receiving bunker without any pre-selection.Biogas is transferred via a pipeline into a central power and heat generation facility downtown Garmisch Partenkirchen, so the gas use is not connected to the plant. All digestate is transferred into the municipal waste water treatment facility next door which is operated by the Gemeindewerke too. The digestate is fully treated so no liquid fertilizer is land applied.

Finsterwalder was responsible for all design works (General Designer) of all systems within the facility. Finsterwalder manufactured and delivered key machine and process technology. Finsterwalder was responsible for general site supervision but not for local site management.

Integrated FINSTERWALDER Technology

- 2x Separation press Biosqueeze BS20

- 1x Double tube heat exchanger for substrate heating

- 1x Double tube heat exchanger contaminants heating

- 1x Floor Scraper

- 1x Sediment Separator SA05

- 1x Skimmer

- Control System

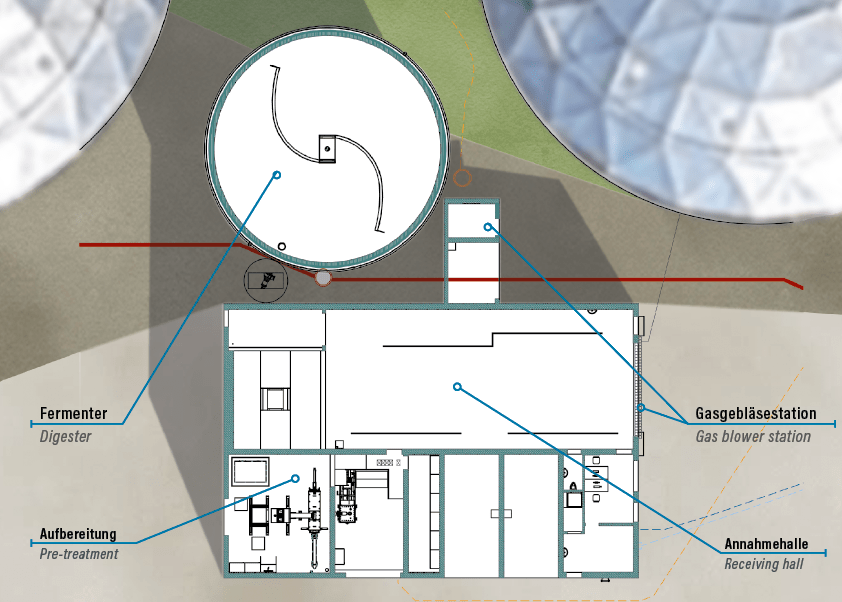

Overview

Waste Treatment Process

Flow Sheet in Detail

RECEIVING BUNKER

The receiving bunker has 200 m³ Volume. The waste is transferred into the pre-treatment by an automated crane system

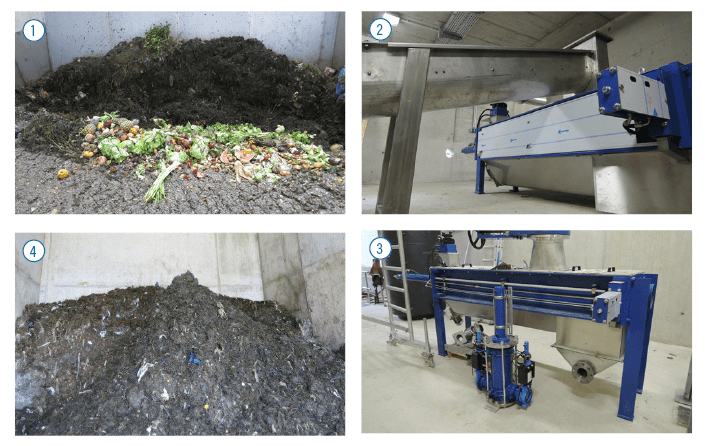

PRE-TREATMENT AND CONTAMINANTS REMOVAL

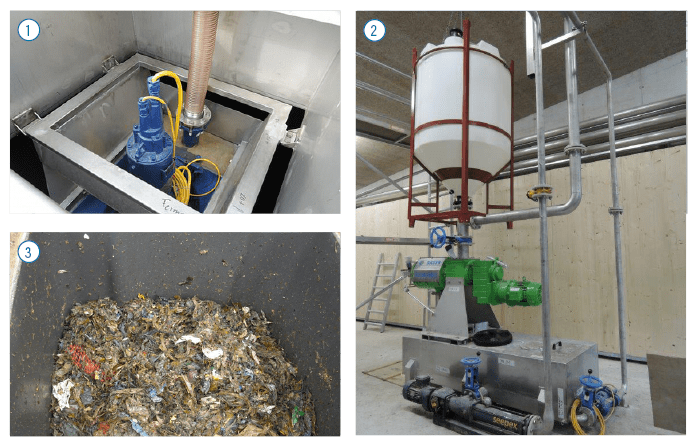

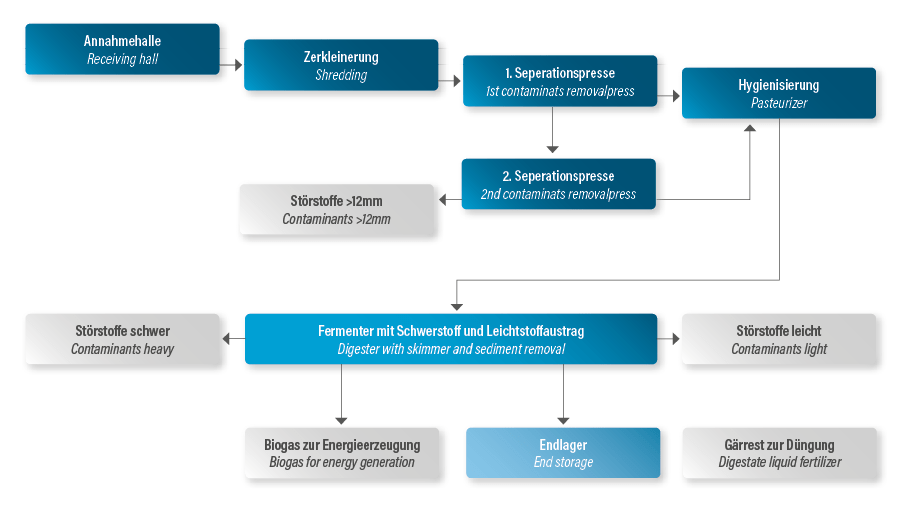

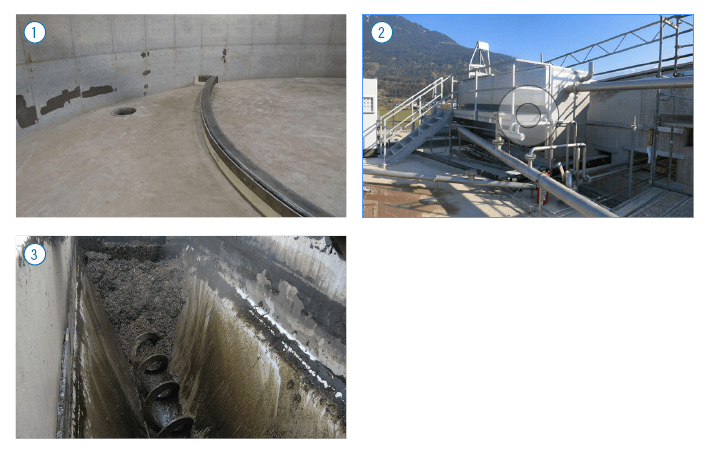

The plant can use different typs of wastes. (1) Waste is shredded with standard technology. The shredded waste is distributed into the Finsterwalder BS20 Biosqueeze contaminats removalpress (2). The liquid substrate is delivered into the double tube heat exchanger. The reject is pushed through a 35m long heat jacketed pipe and heated up to 75°C before second squeeze. (3) Substrate from second squeezing is going to the double tube heat exchanger for pasteurizing too. The solid contaminants with DM content of about 45% are rejected. (4)

HEATING WITH DOUBLE TUBE HEAT EXCHANGER

The double tube heat exchanger heats up the substrate to about 75°C.

FINSTERWALDER SEDIMENT REMOVAL

The digester is equipped with a Finsterwalder BR14 Floor scraper (1) . This moves all solid sediments into an external sediment trap. The sediment separater (2) is emptied in necessary cycles. Currently there are 2 t/d of sand removed from the digesters. (3) Without sediment removal system the digesters would be filled with sand within 2 years of operation.

FINSTERWALDER SKIMMER UNIT

In each of the digesters a skimming unit is implemented. (1) The skimmer removes up-swimming material like fibers and plastic pieces that otherwise would form a mat. The separation is done by an external sieving machine. (2) The solid drop out contains all the plastic. (3)