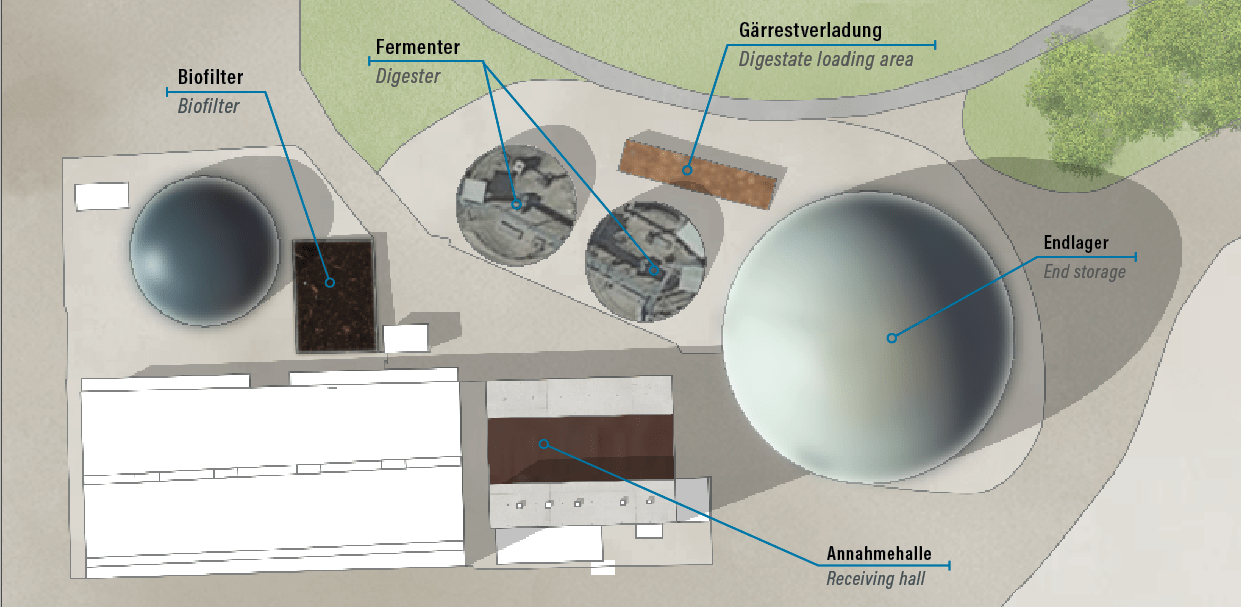

Short Project Description

The AD Plant Rothmühle treats 25.000 t/y of source separated organics collected mainly from private households. The waste is split into two fractions, a course fraction >100 mm with leave and yard waste going into a dry AD process and the fine fraction <100 mm going into the wet AD. Biogas of both systems is collected and used in several CHP. Finsterwalder designed the wet AD and the integration of wet and dry AD. Finsterwalder delivered all technical equipment and installations and commissioned the system. Finsterwalder supervised but was not contracted to serve the civil works.

Integrated FINSTERWALDER Technology

- 2x Separation Press BS20

- 1x Double tube heat exchanger pasteurizer system

- 1x Double tube heat exchanger contaminants heating

- 2x Floor Scraper

- 1x Sediment Separator SA05

- 2x Skimmersystem

- 1x Double Piston Pump KV20

- Control system

Overview

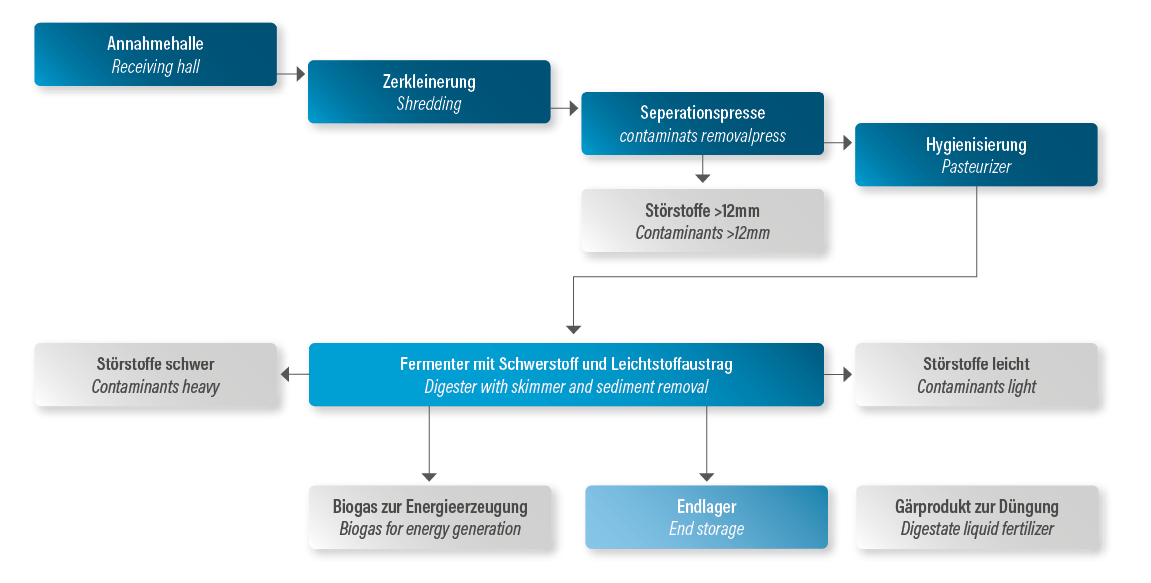

Waste Treatment Process

Flow Sheet in Detail

(1) RECEIVING BUNKER

The receiving bunker has 200 m³ Volume. The waste is transferred into the pre-treatment by an automated crane system.

The receiving bunker has 200 m³ Volume. The waste is transferred into the pre-treatment by an automated crane system.

(2) PRE-TREATMENT AND CONTAMINANTS REMOVAL

Waste is shreded with standard technology. The shredded waste is distributed into two Finsterwalder BS20 Biosqueeze units. The reject is going to composting, the substrate pumpet into the Finsterwalder Pasteurizer (Double tube heat exchanger).

Waste is shreded with standard technology. The shredded waste is distributed into two Finsterwalder BS20 Biosqueeze units. The reject is going to composting, the substrate pumpet into the Finsterwalder Pasteurizer (Double tube heat exchanger).

(3) HEATING WITH DOUBLE TUBE HEAT EXCHANGER

The double tube heat exchanger heats up thesubstrate to about 75°C.

The double tube heat exchanger heats up thesubstrate to about 75°C.

(4) PUMPING TECHNOLOGY

The substrate is delivered into the digesters by a Finsterwalder KV20 Ball Valve Pump. Usual pump technologies are not sufficient because of high total solids content (20 %), temperatures of up to 85°C and amounts of abrasive sand coming with the substrate. (up to 10 % of pumping volume)

The substrate is delivered into the digesters by a Finsterwalder KV20 Ball Valve Pump. Usual pump technologies are not sufficient because of high total solids content (20 %), temperatures of up to 85°C and amounts of abrasive sand coming with the substrate. (up to 10 % of pumping volume)

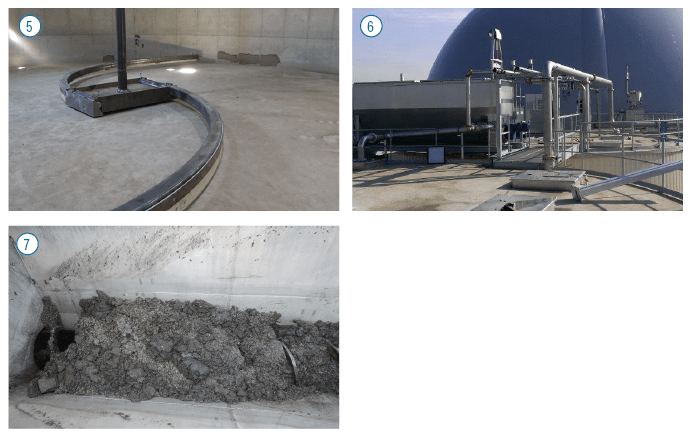

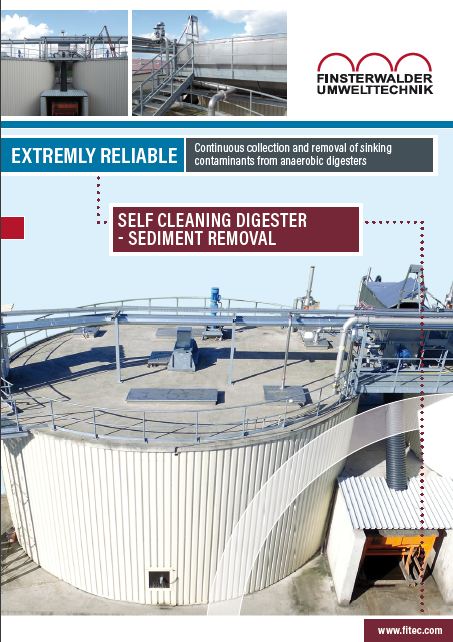

FINSTERWALDER SEDIMENT REMOVAL

In each digester a Finsterwalder BR13 Floorscraper is implemented (5) . This moves all solid sediments into an external sediment trap . The sediment trap (6) is emptied in necessary cycles. Currently there are 8 t/d of sand removed from the digesters. (7) Without sediment removal system the digesters would be filled with sand within 250 days of operation.

In each digester a Finsterwalder BR13 Floorscraper is implemented (5) . This moves all solid sediments into an external sediment trap . The sediment trap (6) is emptied in necessary cycles. Currently there are 8 t/d of sand removed from the digesters. (7) Without sediment removal system the digesters would be filled with sand within 250 days of operation.

FINSTERWALDER SKIMMER UNIT

In each of the digesters a skimming unit is implemented. (8) The skimmer removes up-swimming material like fibers and plastic pieces that otherwise would form a mat. The separation is done by an external sieving machine. (9) The solid drop out contains fibers but also all the plastic. (10)

In each of the digesters a skimming unit is implemented. (8) The skimmer removes up-swimming material like fibers and plastic pieces that otherwise would form a mat. The separation is done by an external sieving machine. (9) The solid drop out contains fibers but also all the plastic. (10)

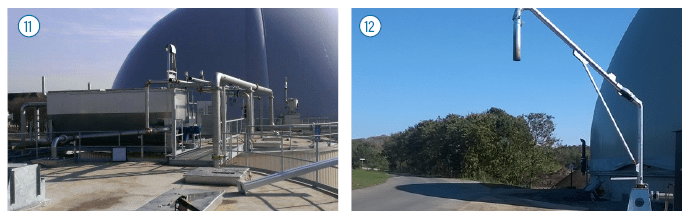

(11) ENERGY USE

The wet AD plant produces about 250m²/h biogas, the dry AD about 125 m³/h. Both gas streams are stored together in a 9000 m³ double membrane gas storage above the end storage tank. Energy generation happens in several CHP units on site. With implementation of the wet AD system 800kWel. power have been installed.

The wet AD plant produces about 250m²/h biogas, the dry AD about 125 m³/h. Both gas streams are stored together in a 9000 m³ double membrane gas storage above the end storage tank. Energy generation happens in several CHP units on site. With implementation of the wet AD system 800kWel. power have been installed.

(12) USE OF DIGESTATE

In each of the digesters a skimming unit is implemented. (8) The skimmer removes up-swimming material like fibers and plastic pieces that otherwise would form a mat. The separation is done by an external sieving machine. (9) The solid drop out contains fibers but also all the plastic. (10)

In each of the digesters a skimming unit is implemented. (8) The skimmer removes up-swimming material like fibers and plastic pieces that otherwise would form a mat. The separation is done by an external sieving machine. (9) The solid drop out contains fibers but also all the plastic. (10)

Latest news

Events

[mapsmarker layer="1"]