Short Project Description

Entsorgungswirtschaft Soest GmbH collects and recycles approx. 30,000 t/a of biowaste at the Anröchte composting plant site. The existing composting plant was expanded to include fermentation in 2020. The tender was won by Hitachi Zosen INOVA AG for the fermentation part. Finsterwalder Umwelttechnik, in turn, was contracted to supply and install the pumping technology for circulation and transfer of the fermentation product from the digester to the composting plant. The pump capacity is adjustable between 12 and 22m³/h at 10bar delivery pressure.

Integrated FINSTERWALDER Technology

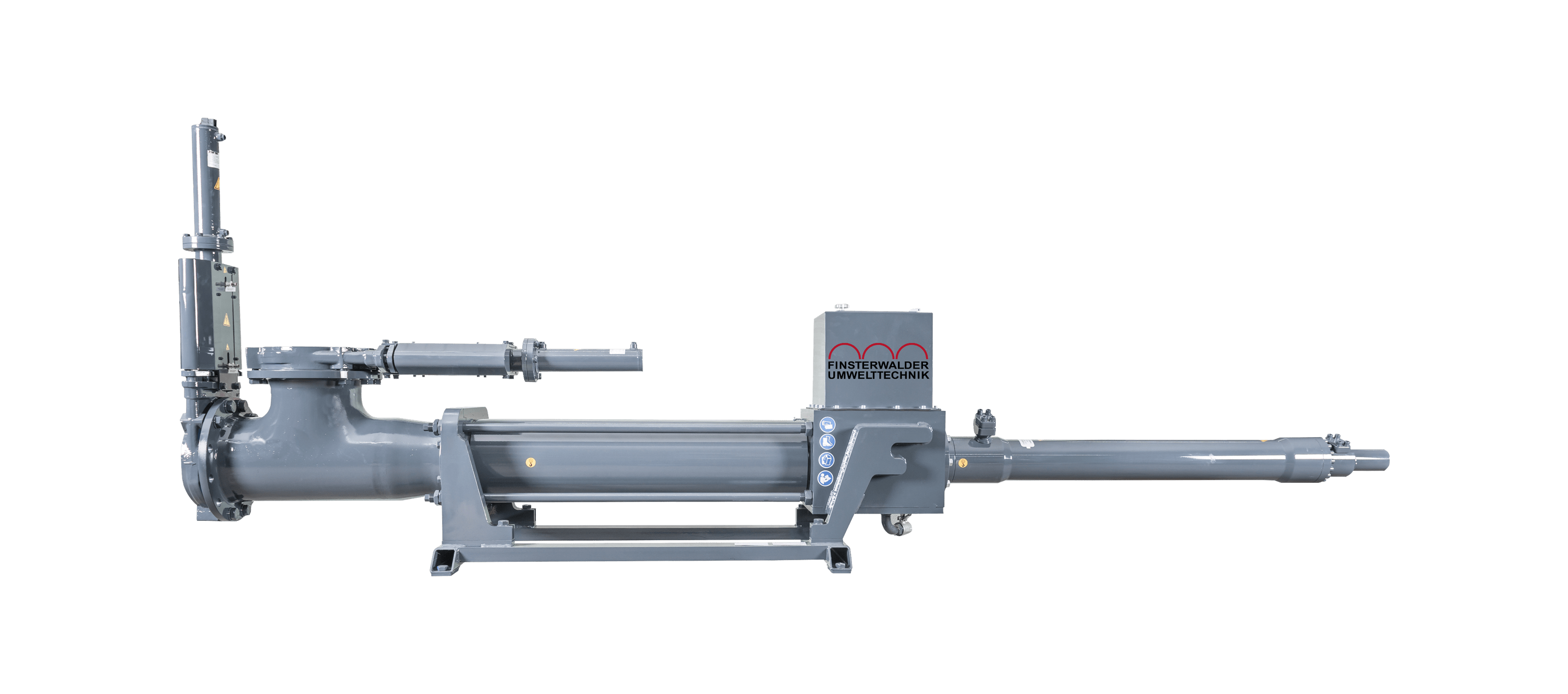

- Gate Valve Pump KS23 – DN250

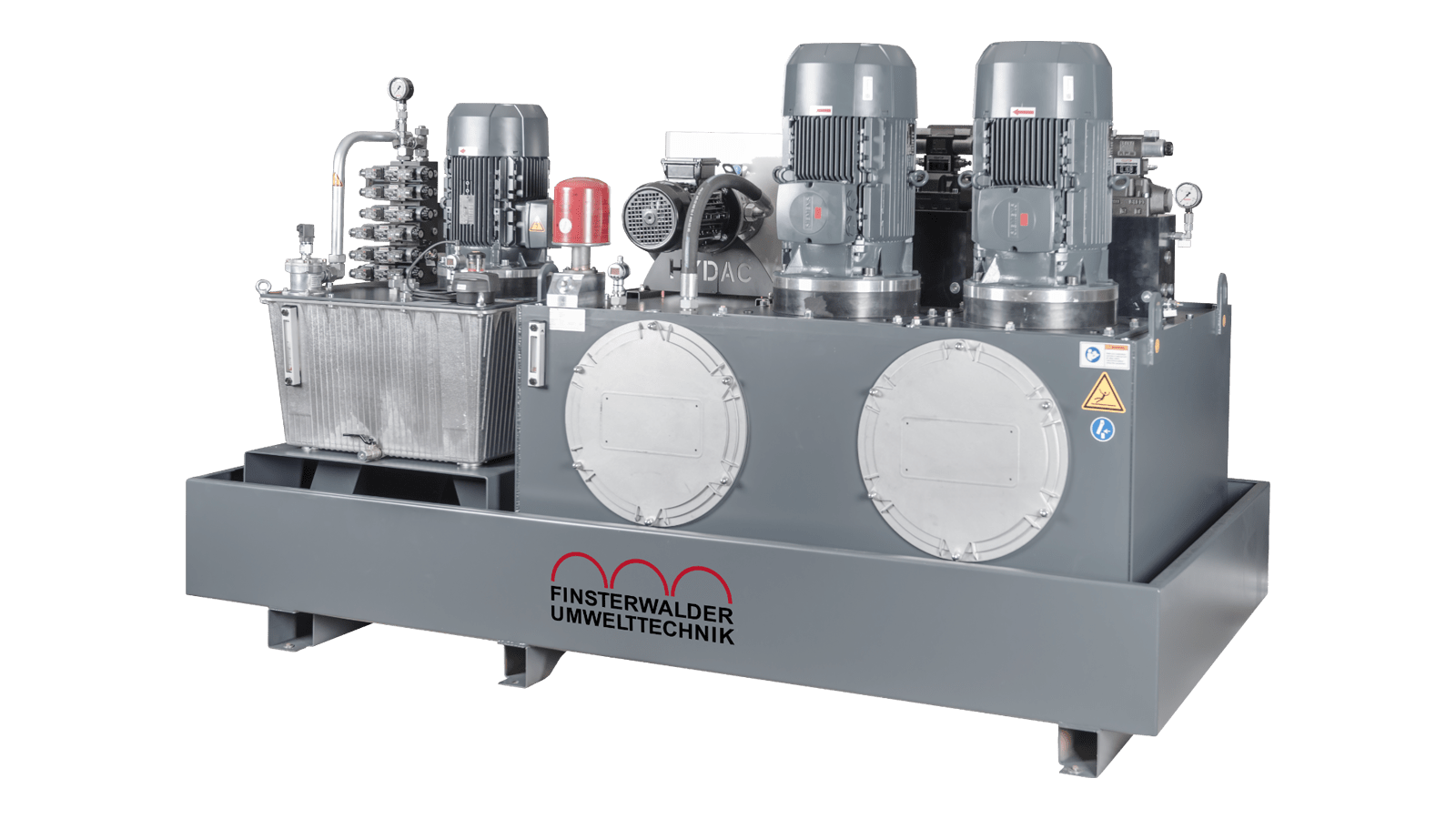

- 1x Hydraulic power Unit 2x 15kW

- Cotrol syste

Services

- Delivery

- Design

- Installation

- Commissioning

- Service

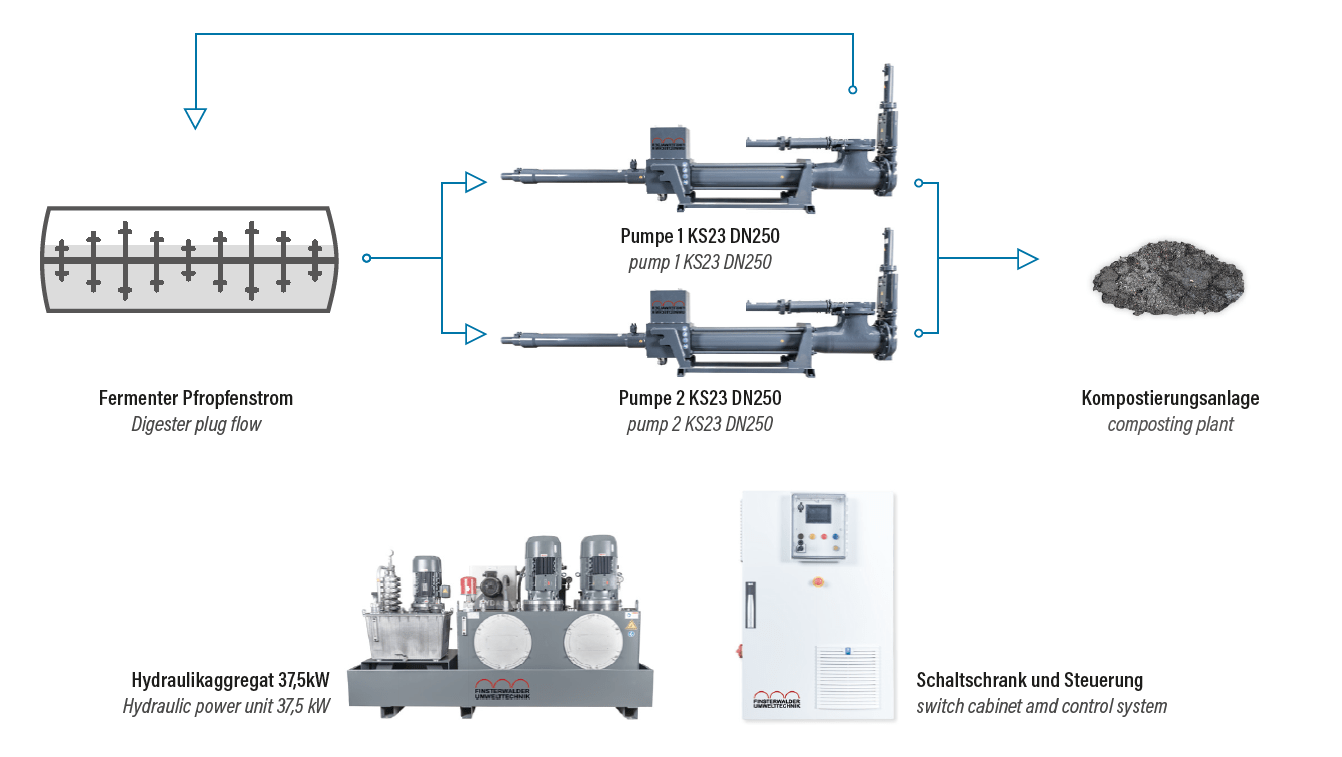

Waste Treatment Process

Flow Sheet in Detail

FINSTERWALDER GATE VALVE PUMP KS23 DN250

The two KS23 gate valve pumps are alternately filled from a DN400 pipe via a Y-piece. One pump pushes

the fermentation product back into the fermenter via a DN250 pipe. Both pumps are operated simultaneously

to continuously transfer the digestate into the compost mixer of the composting facility.

HYDRAULIC POWER UNIT

The hydraulic power unit, which was specially developed for this project, drives both pumps and can also

operate other valves on the system. It has a 600L oil tank, a WHG oil pan and consists of three oil circuits.

SWITCH CABINET AND COTROL SYSTEM

The switch cabinet and the automation were adapted for the project. The aim was to ensure 24-hour automatic

operation and remote access. In addition, the digestate should be sent into the compost mixer as continuously as

possible. For this purpose, frequency converters were installed that allow both pumps to deliver in a coordinated

manner.