A COMMON PROBLEM:

Sediment enters from contaminated organic wastes and accumulates on the digester floor.

This leads to sediment build up and the following problems:

» A decrease in the effective digester volume (retention time) ▷ biological problems

» Damage to mechanical equipment like pumps, agitators, etc.

» Downtime and expensive cleaning of digesters

OUR SOLUTION:

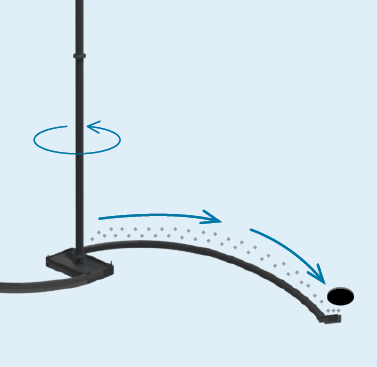

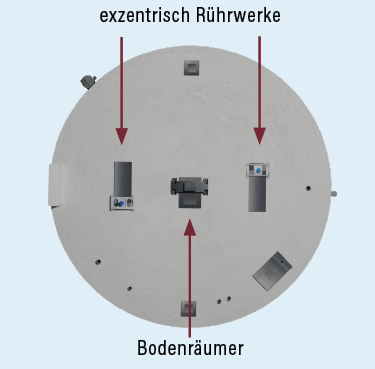

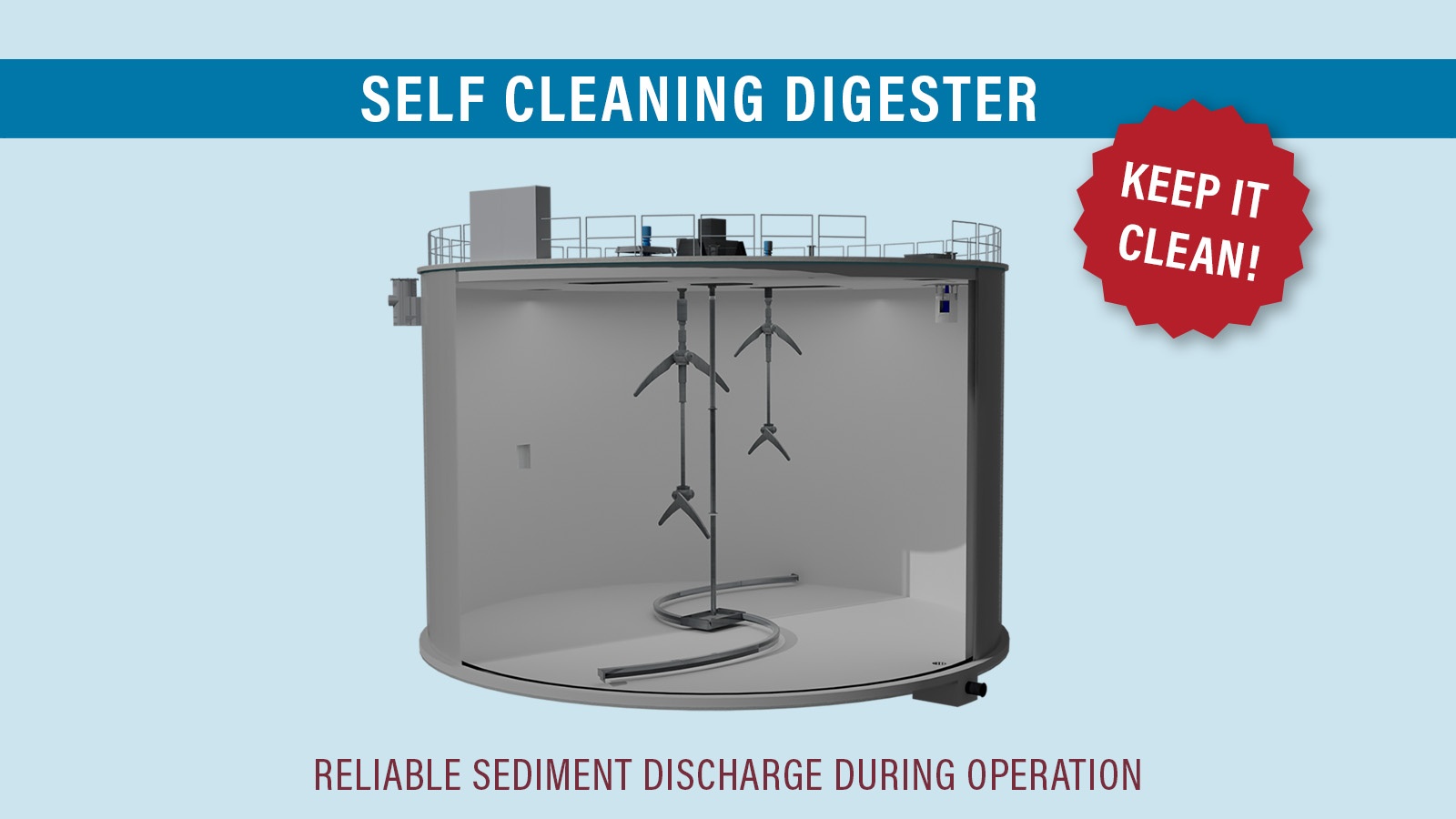

» Sediment buildup is avoided by the regular and fully automated action of the double arm floor scraper.

» Maintains a consistent digester volume ▷ stable biological system

» Protection of mechanical equipment

» Interruption free operation during the cleaning cycles of digester floors

Floor scraper RM10/RM13

Interested in more Information about the patented floor cleaning system?

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.sdf

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

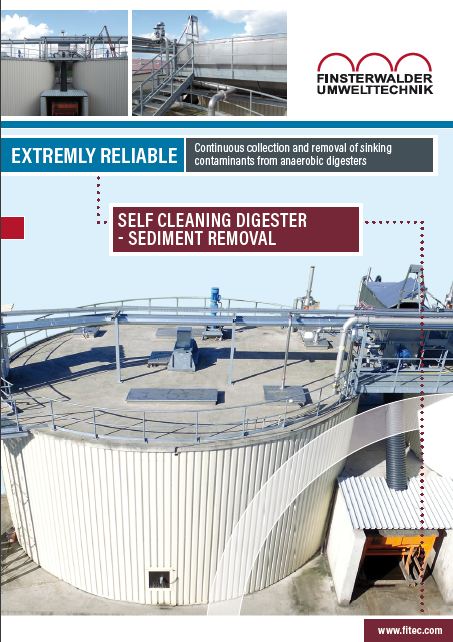

PATENTED FINSTERWALDER FLOOR CLEANING SYSTEM – RELIABLE CLEANING OF CONTAINERS DURING OPERATION

After processing, many organic wastes still contain substances that settle in the fermenter (eg stones, sand, bone fragments, pieces of glass, egg shells, etc.). For fermenters to fulfill their function permanently, these suspended solids must be discharged on a regular basis. The floor cleaning system is used for the continuous discharge of sinking substances from the fermenter. The system consists of the patented mechanical floor scraper, the sediment discharge pump and the sediment separator.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

ALSO A PROBLEM:

Floating Contaminants such as plastic peices, corc resudials or the like, lead to accumulation af floating layers. Consequences:

» disruptions in the biogas production process

» interrupted operation of the plant

» economic losses

» costly elimination of the disturbance

SOLUTION:

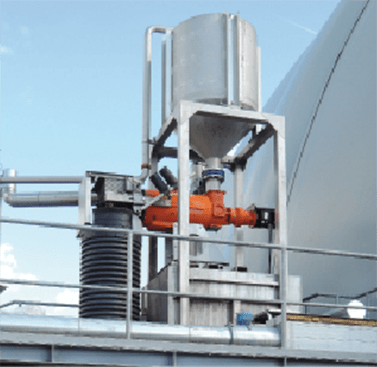

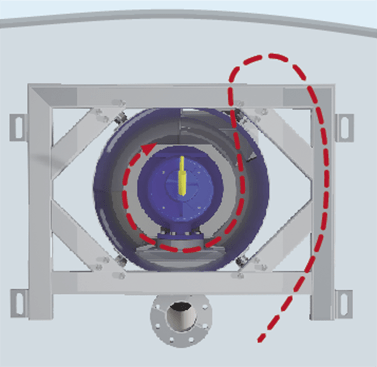

The floating contaminants removal system is made for cleaning digesters during operation. The system consists of a patented skimmer and a standard screw press. Key features of the system include:

» Separation of floating & lightweight contaminants such as plastic from the liquid surface

» Prevention of floating layers

» Easy maintenance access from the top or side

» Gas tight design in any operating condition

» Produces clean digestate

Skimmer LS01/02

Interested in more Information about the patented leather skimmers system?

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.sdf

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

PATENTED FINSTERWALDER FLOOR CLEANING SYSTEM – RELIABLE CLEANING OF CONTAINERS DURING OPERATION

After processing, many organic wastes still contain substances that settle in the fermenter (eg stones, sand, bone fragments, pieces of glass, egg shells, etc.). For fermenters to fulfill their function permanently, these suspended solids must be discharged on a regular basis. The floor cleaning system is used for the continuous discharge of sinking substances from the fermenter. The system consists of the patented mechanical floor scraper, the sediment discharge pump and the sediment separator.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

By this system, the otherwise regularly required and costly clearing of the fermenter (= business interruption) is avoided.

Contact us! We advise you individuall.

Finsterwalder Umwelttechnik GmbH & Co KG

Mailinger Weg 5

83233 Bernau

Tel: +49 (0)8051 965910 0

Fax: +49 8051-965910-20